The Impact of Toyota's Manufacturing Innovations

Toyota's innovative manufacturing techniques led to the popularity of affordable Japanese cars in the US and revolutionized the industry worldwide.

00:00:03 Toyota revolutionized manufacturing with its 'Lean Manufacturing' system, producing over 10 million cars annually. Its success stemmed from creative solutions and working within constraints.

Toyota became the first company to produce over 10 million cars a year.

Toyota's success is attributed to their 'Lean Manufacturing' system.

During the war, Toyota had to be creative due to scarcity of materials.

00:01:06 How Toyota revolutionized production by adopting a 'Just In Time' system, eliminating waste and operating on a tighter budget.

💡 The turning point for Toyota's Production System came when a visit to a Piggly Wiggly supermarket inspired the idea of 'Just In Time' production.

💡 Toyota eliminated waste in the production process by making smaller numbers of parts and producing them when needed, operating on a tighter budget.

💡 The Toyota Production System was a response to the lack of resources in cash-strapped Japan, where companies could not afford to have excess stock sitting in a warehouse.

00:02:12 Toyota revolutionized manufacturing with the development of Kanban and a culture of continuous improvement, creating reliable and affordable cars.

Ohno developed 'Kanban' as a scheduling method, which became a precursor to bar codes.

Toyota noticed American car companies' production techniques and implemented improvements.

Toyota emphasized continuous improvement and created a reliable and affordable car brand.

00:03:15 Toyota revolutionized manufacturing with its efficient production system, leading to the popularity of affordable Japanese cars in the US and influencing industries beyond automotive.

🚗 Toyota's factory efficiencies allowed them to produce a car every 1.6 man hours, appealing to Americans during the oil crises.

🌍 Toyota's 'Lean' principles influenced other industries, such as Boeing and Intel, and even a Canadian Hospital.

🏭 The Toyota Production System revolutionized global car manufacturing and our approach to production.

00:04:25 How Toyota revolutionized manufacturing by demonstrating there is always a more efficient way to make products.

🚗 Toyota revolutionized the way we manufacture products.

💡 They demonstrated that there is always room for improvement in the manufacturing process.

You might also like...

Read more on News & Politics

Sharing My $100K UGC Creator Network System

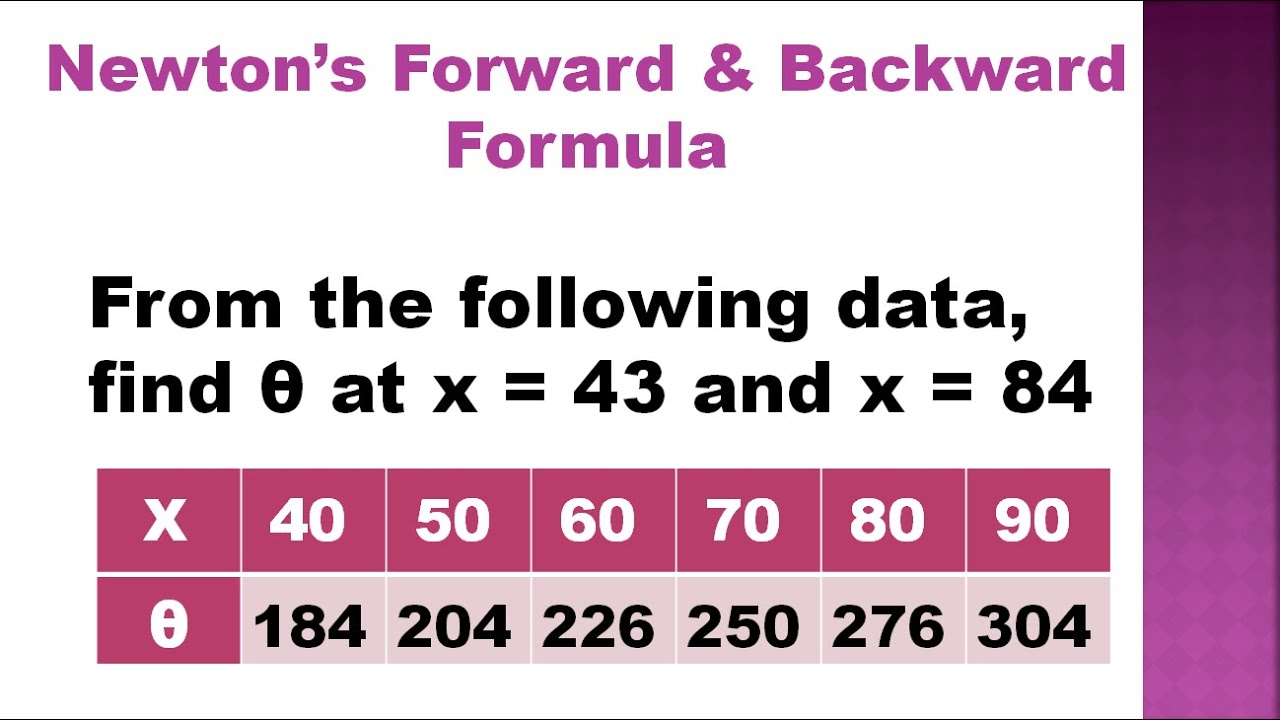

Interpolation| Newton's forward & backward difference formula | Problem in Tamil

![🤖한파고vs최파고🤖대박사건! 오늘은 되는 날~!!한지민프로의 [프로VS아마 27회]](https://i.ytimg.com/vi/GHCt4MxLdis/maxresdefault.jpg)

🤖한파고vs최파고🤖대박사건! 오늘은 되는 날~!!한지민프로의 [프로VS아마 27회]

영원한 따거 주윤발(周潤發) 레드카펫 수상 직캠 @2023 부산국제영화제

Dart Programming Tutorial For Absolute Beginners | Master Dart In 8 Hours | Flutter Tutorial Pt 1

1993: Original GROUNDHOG DAY Review | Film 93 | Classic Movie Review | BBC Archive